- Products

- Solution

- Manufacture

- Service

- News

- About us

- Contact us

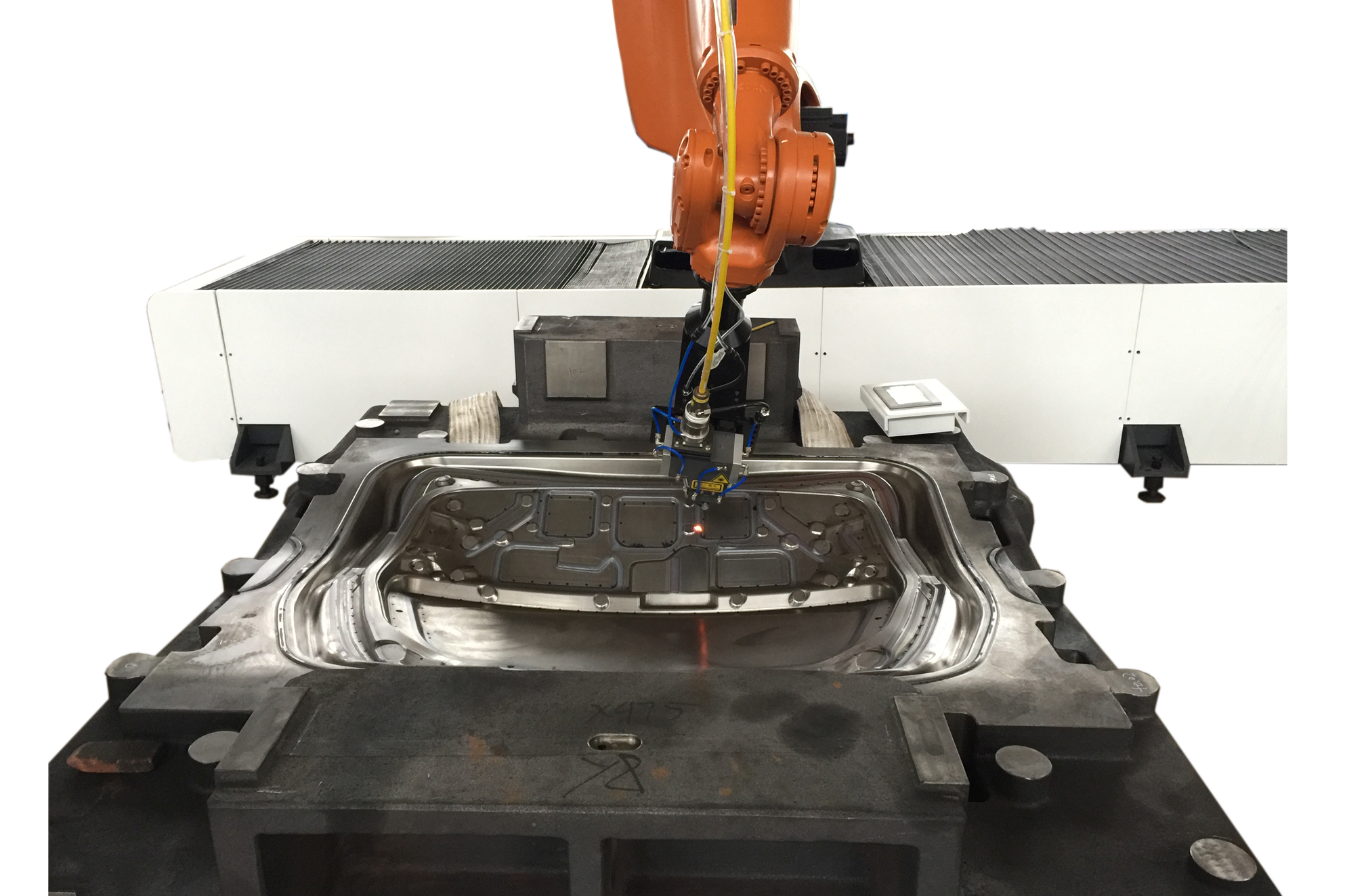

Laser Hardening

Application Industry Automotive industry; automotive stamping dies, automotive injection molds, steam red, gearboxes. Mold industry: Stamping die, seal forging die, extrusion die, injection mold, die-casting die. Machinery: rails. Bearings. Gears. Metallurgy industry: rolling series, saw blade, crane blade.

- Product description

- Specifications

- Sample display

-

- Commodity name: Laser Hardening

- Commodity ID: 1475857179842596864

Application Industry</br> Automotive industry; automotive stamping dies, automotive injection molds, steam red, gearboxes. </br> Mold industry: Stamping die, seal forging die, extrusion die, injection mold, die-casting die. </br> Machinery: rails. Bearings. Gears. </br> Metallurgy industry: rolling series, saw blade, crane blade. </br>

Features:

» Non-joint salmon processing, fast heating and cooling, fast processing speed and short lead time.

» The heat input is stable, the heat-affected zone is small, the deformation is small, the hardness of the microstructure of the metal material is improved and the residual stress is removed, and the fatigue resistance of the metal material is effectively improved.

» It adopts flexible optical path selection processing, which does not affect other areas, and the hardening layer is controllable, thereby improving processing efficiency, improving material hardness and wear resistance.

» No damage to the surface of the workpiece after quenching, no secondary processing, no cracking on the mold surface, stable and uniform hardness of the hardened layer.

» Strengthened by self-quenching of the matrix, no quenching medium is required, the processed part does not decarburize, the stability of the material does not change, and it can be quenched repeatedly.

» Short thermal cycle time, small structure, only higher strength and fatigue resistance.

-

Sample display:

Laser quenched sample

Laser quenched sample

The previous one

Contact us

400-885-0505

Company Address

No. 66, Tonghe Road, Weiting Town, Suzhou Industrial Park

Website

Douyin

导航下拉添加类名.active

在线客服添加返回顶部

屏蔽页面上图片的alt/title提示

右侧在线客服样式 1,2,3 0

图片alt标题设置: Tianhong

表单验证提示文本: The content cannot be empty!

循环体没有内容时: Sorry, no matches found.

CSS / JS 文件放置地