- Products

- Solution

- Manufacture

- Service

- News

- About us

- Contact us

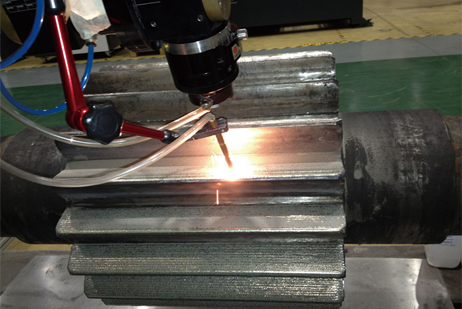

Laser Ccladding Remanufacturing

Typical application Electricity (steam turbine rotors, blades). Mining (gears, drills, hydraulic rods). Machinery (shafts, gears). Petrochemical (turbine discs, rotors, sucker rods). Ships (crankshafts, engine blades, camshafts). Locomotives (Shafts, steam turbine blades, bogies, pistons), molds (stamping dies, forging dies, die-casting dies) and other industry failure parts, the quality of remanufactured products is reliable, and has good economic and social effects.

- Product description

- Specifications

- Sample display

-

- Commodity name: Laser Ccladding Remanufacturing

- Commodity ID: 1475857181306408960

Typical application</br> Electricity (steam turbine rotors, blades). Mining (gears, drills, hydraulic rods). Machinery (shafts, gears). Petrochemical (turbine discs, rotors, sucker rods). Ships (crankshafts, engine blades, camshafts). Locomotives (Shafts, steam turbine blades, bogies, pistons), molds (stamping dies, forging dies, die-casting dies) and other industry failure parts, the quality of remanufactured products is reliable, and has good economic and social effects. </br>

Features:

For mechanical parts that are worn, corroded, creeped, fatigued, and fractured, laser cladding technology is used to synchronously send alloy powder into the molten pool, and rapidly solidify to form a cladding layer with special properties. The cladding layer has no pores and crack defects, and the hardness range is 20~60HRc, which meets various working conditions and performance requirements. It is suitable for cladding/remanufacturing of large parts with complex shapes, restoring the size and performance of failed parts, upgrading surface properties and prolonging service life.

Process features:

» Low heat input, small heat-affected zone, small deformation, and only a small amount of machining.

» The dilution rate is less than 2%, which can maintain the specific properties of the cladding layer.

» Flexibility, automation, short processing cycle, low cost, and better performance than new products.

-

Sample display:

Laser cladding remanufacturing samples

Laser cladding remanufacturing samples

The previous one

Next

Contact us

400-885-0505

Company Address

No. 66, Tonghe Road, Weiting Town, Suzhou Industrial Park

Website

Douyin

导航下拉添加类名.active

在线客服添加返回顶部

屏蔽页面上图片的alt/title提示

右侧在线客服样式 1,2,3 0

图片alt标题设置: Tianhong

表单验证提示文本: The content cannot be empty!

循环体没有内容时: Sorry, no matches found.

CSS / JS 文件放置地