Cleaning subcategory 1

- Categories:清洗下属子分类

- Time of issue:2022-10-14 13:24:09

- Views:0

Laser Cleaning

The so-called laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface of the workpiece is instantly evaporated or peeled off, effectively removing the surface of the workpiece adhesion or coating. The cleaning process is realized by cleaning the cleaned object at high speed. It is a new technology based on the interaction between laser and material, which has obvious advantages over traditional cleaning methods such as mechanical cleaning, chemical corrosion cleaning, liquid-solid strong impact cleaning and high-frequency ultrasonic cleaning.

Cleaning method

Dry Laser Cleaning

Wet Laser Cleaning

Laser plasma shockwave technology

Cleaning material

Rust removal on metal surfaces

Removal of dust and deposits on the surface of the statue.

Rubber Abrasive Residue Cleanup

Typical Application - General Purpose Laser Cleaning machine

General Purpose Laser Cleaning machine

Tianhong laser provides portable removable laser cleaning machine solution.

Mainly used in the mold industry, automobile manufacturing, sewage treatment, rubber tires and other industries. Surface rust removal; surface paint removal and paint stripping treatment; surface oil, stain and dirt cleaning; surface plating and coating removal; rubber mold residue cleaning, etc. can be performed.

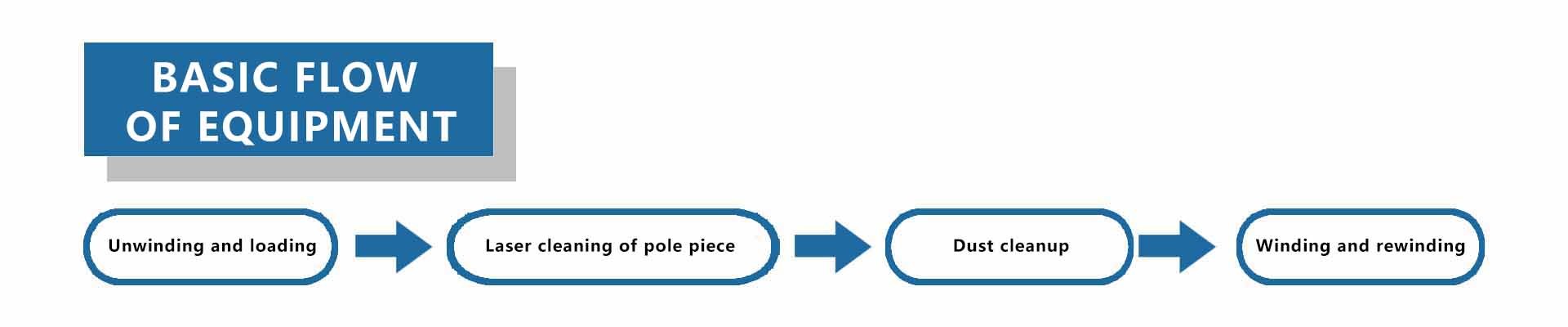

Typical Application-New Energy Laser Cleaning Machine

Laser pole piece cleaning machine

Tianhong laser provides new energy laser cleaning machinesolution.

Mainly used in lithium battery cell, laser cleaning pole piece coating, so that the surface of the pole piece can generate micro-nanometer structure, cleaning depth can be adjusted according to the actual needs.

Blue Film Laser cleaning machine

In recent years, with the demand for new energy vehicles greatly mention, Some phenomena can not be avoided in the production process of automotive new energy batteries, such as uneven blue film paste, bubbles wrinkles and so on.For these defective products, the blue film will need to be removed and reapplied.

Tianhong Laser is a digital intelligent equipment and automated production line provider with laser technology as the core, provide a new energy battery blue film laser cleaning equipment, which can significantly improve the new energy battery blue film cleaning efficiency and product quality, reduce labor costs.

Process Features

High cleaning efficiency

Laser cleaning is efficient and time saving.

Precision cleaning

Precision cleaning with programmable light output width.

Non-contact cleaning

Non-contact cleaning with virtually no damage to the substrate surface

Wide cleaning range

Stainless steel, carbon steel, aluminum, copper, alloy and other metal materials are applicable

Stable cleaning system

The laser cleaning system is stable and virtually maintenance-free.

Safe and environmentally friendly

No chemical cleaning solution, no consumables, can use when power is on.

Industry Application

New Energy Industry

Sewage treatment

Rubber tire

Petrochemical

航空航天

Mould Industry

Automobile Industry

Shipping Industry

Advantage

OFTWARE

MOTION CONTROL SYSTEM

OPTICAL SYSTEM

Clean样式表

Clean样式表

Contact us

Company address

No. 66, Tonghe Road, Weiting Town, Suzhou Industrial Park

Website

Douyin